Distributor of standard & custom linear & vision measuring systems. Machines can perform 2D & 3D non-contact inspection, dimensional measurement & other functions. Also offers consulting, design & testing services.

Vision measuring machines use cameras to detect features on workpieces. The software then constructs a feature, such as a line or diameter. They can be used for a wide range of applications and are usually more cost-effective than optical comparators or measuring microscopes.

VISIONx Inc.

VISIONx Inc. develops support software, systems and specialized hardware components for machine vision, visual inspection, image analysis and general defect detection. It also manufactures VisionGauge Digital Optical Comparators/Profile Projectors. The VisionGauge vision measurement system provides a cost-effective field of view (FOV) solution designed for smaller parts. It can compare directly to CAD data and eliminate the need for mylars, overlays or charts.

Using five axes of motion, the 700 Series VisionGauge can verify hole presence and location on shaped and round holes. It can also transfer data directly from an electric discharge machining (EDM) drill or machine tool.

The company’s newest upgrade allows users to supply the VisionGauge with CAD hole coordinates directly from an electronic design automation (EDA) tool or CAM application. This reduces operator training and ensures that the correct hole data is used for each part. It also reduces the possibility of misinterpreting incorrect or inconsistent dimensional information and improves efficiency. In addition, the VisionGauge doesn’t require contact with a workpiece, removing the risk of defacing or damaging a lightly fixtured part.

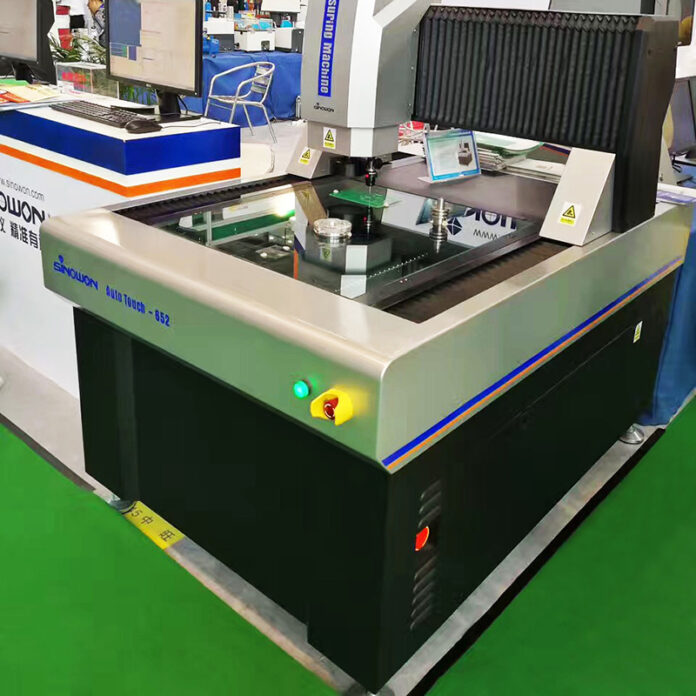

Sinowon Innovation Metrology Manufacture Limited

In industries where precision is vital, vision measurement machines can boost efficiency and accuracy in a variety of ways. They can be utilized during the research and development phase of product production to ensure that prototypes meet specifications, and during manufacturing to verify that manufactured parts fit correctly. They also provide a valuable tool for quality control procedures and boost productivity by minimizing the likelihood of defective parts making it into the supply chain.

Machine vision systems use cameras and lenses to capture images of the components being measured, which removes the need for direct physical contact. This reduces the possibility that components would be damaged by the measuring process, as well as eliminates the need for regular calibrations.

Sinowon Innovation Metrology Manufacture Limited is a China authorized hi-tech ISO9001: 2015 manufacturer of metrology instruments, focusing on researching, developing, manufacturing and exporting optical measurement instruments and hardness testing machines since 2006. Their high-quality products include Optical Instant Video Measuring Machine, Profile Projector, Manual/Automatic Video Measuring Machine, Toolmaker Microscope, and Metallurgical Microscope.

Starrett

Starrett offers a broad range of vision measurement systems for both QA labs and production floors. For example, the company’s HDV horizontal digital video comparator combines vision and optical comparator technology in a compact frame. It offers a choice of seven telecentric lenses and minimizes optical distortion to provide precise field-of-view (FOV) measurements.

The system also enables automatic edge detection, which locates the edges of the part being measured and compares it to an engineering design without the need for Mylar overlays. This reduces operator subjectivity and increases measurement throughput.

Choosing the right vision system for a shop depends on a few factors. First, a shop should identify the types of parts for which it will need inspection and measurement. Then, it should choose the appropriate software and accessories. Finally, a reputable supplier can help with installation and training of the equipment on a shop floor and provide ongoing technical support, including annual calibration. A supplier can also help select a proper configuration that will best suit the needs of a specific application.

Met Optix

The company provides precision optical design, manufacturing, testing, and distribution of standard and custom solutions for a wide range of applications, including machine vision, digital projection, industrial imaging, and R&D. It offers a variety of lens, filter, and assembly technologies, as well as advanced optical measurement systems. Its product portfolio includes polarization optics, crystals, assemblies, megapixel CCTV lenses, and 20 MP machine vision lenses.

Medical part inspection and traceability can be challenging for shops. Whether working with highly reflective finishes, unique thread specifications, or micro-etching, it’s important to coordinate with a metrology system supplier that understands these distinctive challenges.

A smart camera vision system (SCVS) has a single view and provides a limited number of functions on that view. For example, a SCVS on a bottling line might read a barcode, verify the date and lot code, check for the presence and position of a label, and ensure that a bottle’s closure is seated. It can also be equipped with touch probes to capture discrete points that are hard for a vision process to “see.” The latest Visual Measurement Equipment market research report is now available, featuring insights into competitive analysis and predicted outcomes through to 2028.