Introduction: The Evolution of End-of-Line Automation

In today’s fast-paced business landscape, optimizing operational efficiency has become paramount for companies across industries. One of the key advancements that have revolutionized manufacturing and logistics is end-of-line automation. This technology-driven approach holds the potential to reshape how businesses handle their final production stages, enhancing productivity, reducing errors, and ultimately delivering a competitive edge. This article explores the concept of end-of-line automation and its transformative impact on various sectors.

Understanding End-of-Line Automation

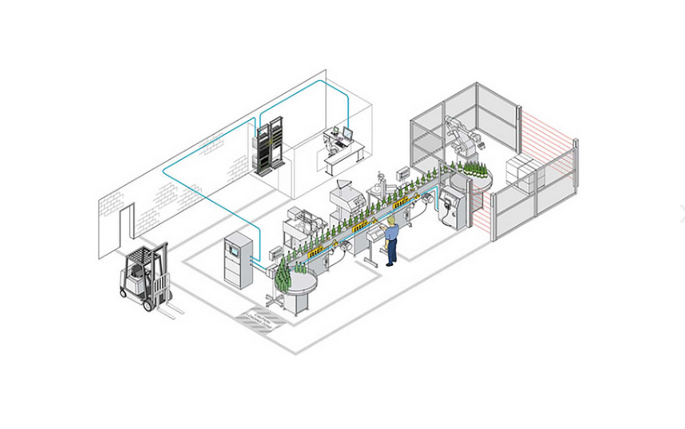

End of line automation refers to the integration of advanced technologies and robotics at the final stages of the production process. It encompasses tasks such as packaging, labeling, sorting, and quality control, all of which traditionally required significant manual labor and time. By automating these processes, businesses can achieve higher accuracy, consistency, and speed while freeing up human resources for more complex tasks.

The Benefits of End-of-Line Automation

- Enhanced Efficiency and Throughput: Automation accelerates processes that were previously time-consuming and labor-intensive. This results in increased production throughput, shorter cycle times, and a higher overall output.

- Improved Quality Control: Automated systems can consistently and accurately inspect products, minimizing defects and ensuring that only high-quality items reach the market. This leads to fewer recalls and improved customer satisfaction.

- Cost Savings: While the initial investment in end-of-line automation systems can be substantial, the long-term cost savings are significant. Reduced labor costs, minimized waste, and optimized resource allocation contribute to improved profitability.

- Workplace Safety: Automating repetitive and potentially hazardous tasks reduces the risk of workplace injuries, creating a safer environment for employees.

- Scalability: As businesses grow, end-of-line automation systems can easily scale to accommodate higher production volumes without proportionately increasing labor needs.

Applications Across Industries

- Manufacturing: End-of-line automation is a game-changer in manufacturing. Robotic arms can efficiently package and palletize products, while automated conveyors ensure seamless movement throughout the production facility.

- Food and Beverage: In the food and beverage industry, end-of-line automation ensures consistent packaging and labeling, maintaining hygiene standards and regulatory compliance.

- Pharmaceuticals: Automation enhances the precision and traceability of pharmaceutical packaging, reducing the risk of errors and contamination.

- E-commerce and Logistics: Automating order fulfillment, sorting, and packaging in e-commerce warehouses accelerates delivery times and reduces shipping errors.

Overcoming Implementation Challenges

While the benefits of end-of-line automation are compelling, successful implementation requires careful planning and consideration.

- Integration Complexity: Integrating automation systems into existing workflows can be complex. Thoroughly assessing current processes and designing a seamless integration plan is crucial.

- Skill Set: The transition to automated systems may necessitate a shift in the skill set of the workforce. Upskilling employees to operate and maintain these systems is essential.

- Initial Investment: The initial costs associated with acquiring and installing automation technology can be significant. Businesses need to weigh these costs against long-term savings and gains.

- Customization: Every business has unique needs. Customizing automation solutions to align with specific processes and products is essential for optimal results.

The Future of End-of-Line Automation

As technology continues to advance, the potential of end-of-line automation is poised to grow even further.

- AI and Machine Learning: Incorporating artificial intelligence and machine learning can enhance automation systems’ ability to adapt, learn, and optimize processes over time.

- Collaborative Robots (Cobots): Cobots work alongside human operators, facilitating tasks that require both human judgment and precision, thus expanding the scope of automation.

- IoT Connectivity: The Internet of Things (IoT) can enable real-time monitoring and control of automated processes, allowing for remote management and predictive maintenance.

Conclusion: Embracing the Future of Manufacturing and Logistics

End-of-line automation marks a significant leap forward in how businesses approach the final stages of production. By embracing advanced technologies and robotics, companies can achieve unparalleled efficiency, accuracy, and cost savings. As industries evolve and adapt to changing market dynamics, end-of-line automation stands as a beacon of innovation, offering a pathway to sustainable growth, improved product quality, and a competitive advantage in the global marketplace.