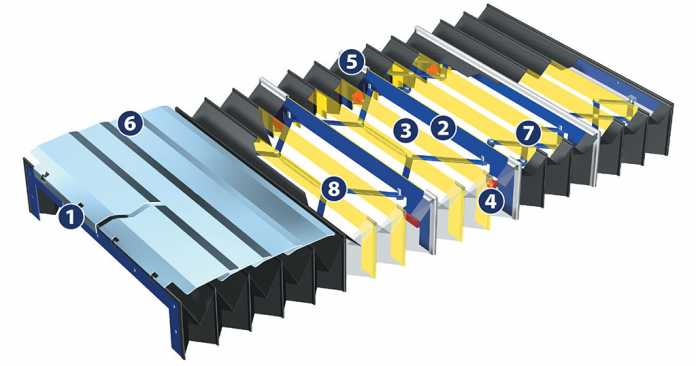

The bellows covers are designed according to the machines. These covers are highly functional as they protect the machine and machine parts from dust and other environmental factors. You need to get the best bellows covers for the machines. The bellows covers are also known as CNC Bellows.

Different features of bellows covers that make them special

You might be interested in knowing the characteristics and features of the bellows covers. These features make the bellows covers quite effective for the machines. The bellows covers are used for the equipment and protect it. You can use the bellows covers to protect the machine from sudden step-by-foot.

They can also protect by saving the repairing cost and time and reduce the cost. Most importantly, the bellows covers are beneficial as they protect from deformation and corrosion and improve the machine’s lifespan.

The best quality bellows covers are made up of high-quality material according to the machine’s requirements, occasion, and design. They are specially designed to fit the machine and have long travel strokes, nice quality, long durability, and fast-moving strokes.

Some famous types of bellows covers

There are certain types of bellows covers that you can find in the market. You can choose the best type according to your requirements and machine. Some of the most famous types of bellows covers are as follows.

- Quadrangular pyramid type bellows covers

- Lift table bellows covers

- Stainless steel bellows covers

- Linear slide bellows covers

- Rectangular bellows covers

- U-type bellows covers

- Flat-type bellows covers

Users are free to choose the type of bellows covers according to the machine and requirements. The best they need to do is to find the most suitable manufacturers of bellows covers. This is how you can have the best bellows covers for CNC machines.

Applications and uses of the bellows covers

Because of their features and applications, there is a high demand for bellows covers. The bellows covers are commonly used on scissor lift tables, hydraulic lift tables, and other lift tables. These are also used in precision electronic equipment, stone cutting machines, glass cutting machines, automatic equipment, CNC machine, laser cutting, machine, and machine tool equipment. You need to get the most Protective Bellows.

The best you need to do is to get the best CNC bellows. The CNC bellows and covers are used in medical control equipment on laser cutting machines. These are the most used in different fields, such as precision measurement, automatic control, medical equipment, and food technology. These are most importantly used in the manufacturing of high-quality and non-toxic machines.

You can find the major use of bellow covers in hydraulic lift tables and car installation production lines. These are suitable for lifting large-sized tables. These can also be customized and manufactured.

The clients are free to choose the cloth and design of the bellows covers according to the choice and machine. The bellows covers are suitable to protect from corrosion as they are antistatic. They also protect from acid, oil, dust, high compression, and water.

The final words

The points mentioned above are the most important things to know about the bellows covers. These points show the features, applications, and types of bellows covers. It would be great to find the best way covers CNC machines.