The concept of a T-slot aluminum may seem complicated; however, it is pretty simple. Each end of a piece of aluminum is shaped like a “T,” allowing users to combine it with other aluminum components. This can be done without welding and is perfect because the pieces are modular, i.e., they are easily changeable.

Users can move and connect the profiles to fit their needs. They can use other added accessories (i.e., angle connectors) to hold the two pieces together firmly. T-slot aluminum pieces allow users to create various structures, including tradeshow booths, conveyors, workstations, and furniture.

Why are they the best bet?

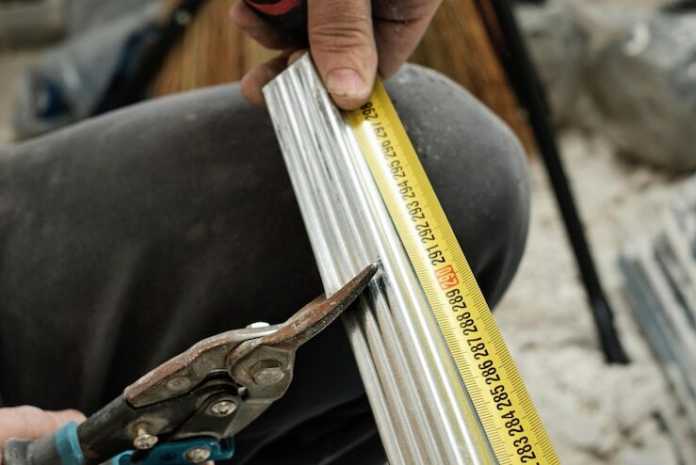

T-slot aluminum is the best because it’s versatile and flexible, which is essential to a manufacturing engineer’s needs. Creating structures with T-slot aluminum pieces is perfect since you don’t have to clamp or weld them together. T-slot aluminum is better to work with than welded steel because you can lengthen or shorten it according to need.

Additionally, the material is corrosion-resistant and robust. Additionally, it’s the perfect material to use in winter since it gets stronger when the temperature drops. Lastly, they are cheaper than steel since it has to be welded and painted, costing you more time and money.

Why do T-slot aluminum profiles have different widths?

There are two main reasons why T-slot aluminum profiles have different widths. They include design and loading capability.

Design

- slot aluminum profiles have varying widths by design to create harmony. Pieces with a small cross-section has a small slot, while those with a big cross-section have a bigger slot. For instance, 4040 T-slot aluminum profiles have 8mm slots, while 2020 T-slot aluminum profiles have 6mm slots. However, they’ll also have an extra 0.2mm allowance of the stated slot size used for installing nuts and bolts.

Loading capability

Structure users can design with T-slot aluminum pieces range from light to heavy, and profiles are designed to fit this range depending on the structure’s stress intensity. For instance, you can use small slot aluminum pieces for light frame structures and large slot aluminum components for heavy structures with a high-stress intensity.

Large aluminum profiles require larger slots to meet the structure’s load-bearing requirements. Installing T-slot aluminum profiles with smaller slots, specifications for installed aluminum profile fittings will be smaller.

This will affect the aluminum profile fittings’ capability to bear the weight of the structure leading to fractures that will affect structure use later.

Alternatively, fitting large slots with T-slots with small aluminum profiles wastes resources. Remember that wider slots and larger bolts and nuts provide greater structural strength.

Why should you take your time choosing T-slot aluminum profiles?

There’s a wide array of T-slot aluminum profiles to choose from, covering various applications. Choosing the right profile for your applications depends on strength, function, appearance, or all three. You should first consider your expected load before selecting an aluminum profile.

Calculate the stress your load causes to help you get the correct profiles. Doing this help you prevent instances where your profile cracks. You should get in touch with a professional aluminum profile supplier if you aren’t sure which profile or accessory you need.

Click here for more blogs.