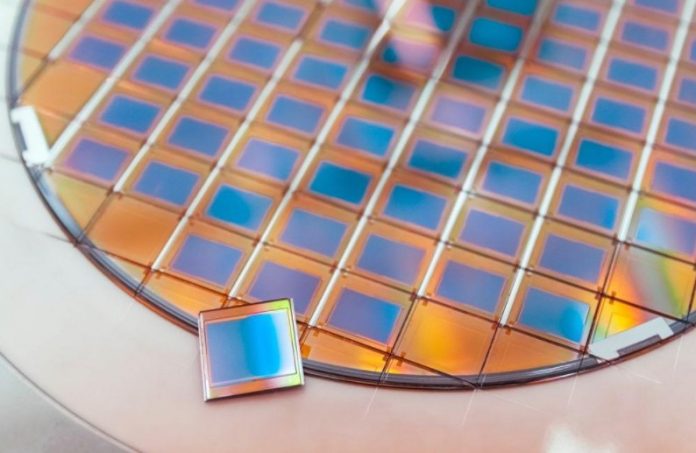

When you talk about semiconductor fabrication, one of the most important steps is the wafer preparation technique. This is where device manufacturers start by removing the unwanted material from silicon wafers. Wafer Coring preparation techniques can be done in a few different ways, but the most common is chemical etching. This process uses chemicals to remove material from the surface of the wafer. In this blog post, we will discuss some of the benefits and challenges of using wafer preparation techniques, and how you can use them to improve your manufacturing process.

What is the Wafer Preparation Technique?

The wafer preparation technique is the step that precedes the fabrication of semiconductor devices on a silicon wafer. It includes cleaning and polishing of the silicon wafer to create a clean, flat surface on which the device components can be fabricated. The wafer preparation technique also includes preparing any masking or adhesives that will be needed for the subsequent device fabrication steps.

What are the benefits of using the Wafer Preparation Technique?

The wafer preparation technique is a process that is used to create a chip from a piece of silicon. The technique begins by cutting the silicon into small pieces and then using a patterning tool to create channels on the surface of the silicon. These channels are then filled with epoxy and allowed to harden. Once the epoxy has hardened, the chip can be cut out of the silicon and used in devices.

There are several benefits to using the wafer preparation technique. First, it allows for very precise control over how devices are made. This precision is important because it enables devices to be designed specifically for each type of silicon material. Second, using the wafer preparation technique allows for very fast manufacturing processes. This is because the channels can be created quickly and filled with epoxy without having to wait for the material to solidify. Lastly, using the wafer preparation technique reduces scrapage during manufacturing processes and therefore reduces costs associated with waste products.

How to use the Wafer Preparation Technique?

Wafer preparation technique is a process that is used to reduce the size of silicon wafers. This technique helps to create wafers that are more accurate and consistent in their manufacturing. In addition, this process allows for the creation of devices with smaller footprints. The most common application for this technique is the creation of microchips.

Conclusion

There are many different types of wafer preparation technique, and the most important factor is to find one that is comfortable for you. Some popular methods include screen printing, laminating, and ink jetting. In order to make sure you get the best results from your wafer preparation technique, be sure to research it thoroughly and experiment with different techniques until you find one that works best for you.