Embroidery digitizing is a meticulous process that involves converting artwork into digital embroidery files that can be stitched onto fabric with precision and accuracy. One essential aspect of digitizing is the underlay stitch, a foundational element that provides stability, density, and definition to embroidered designs. In this comprehensive guide, we’ll delve into the world of underlay stitch for embroidery digitizing, exploring its importance, types, techniques, and best practices to achieve high-quality and precise embroidery designs.

Understanding Underlay Stitch

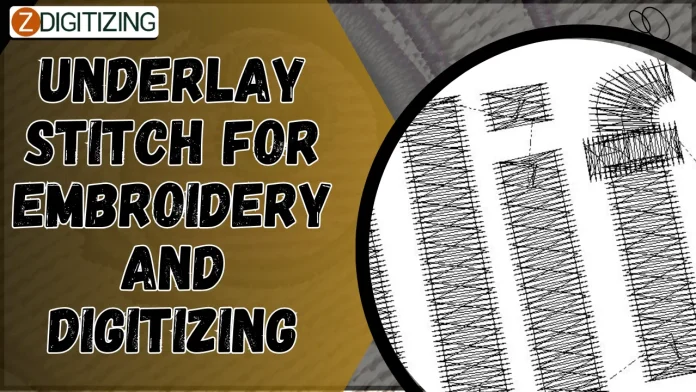

Underlay stitch is a series of stitches laid down beneath the main elements of an embroidery design. Its primary purpose is to stabilize the fabric, create a solid foundation for subsequent stitches, and prevent distortion or puckering during the embroidery process. Underlay stitch also helps improve the overall quality and appearance of the finished embroidery by providing support and density to the design.

Importance of Underlay Stitch in Embroidery Digitizing

- Stability: Underlay stitch stabilizes the fabric by securing it to the backing material, preventing shifting or stretching during the embroidery process.

- Density: By adding layers of stitches beneath the main design, underlay stitch increases the density of the embroidery, resulting in sharper and more defined edges.

- Coverage: Underlay stitch ensures that the fabric is fully covered by subsequent stitches, preventing gaps or uneven areas in the embroidery design.

- Prevents Puckering: Properly executed underlay stitch helps minimize puckering or distortion of the fabric, resulting in a smoother and more professional-looking finished product.

- Supports Complex Designs: For intricate or detailed designs, underlay stitch provides essential support and structure, allowing the embroidery machine to accurately stitch complex patterns with precision.

Types of Underlay Stitch

- Center Run: A single line of stitches running through the center of the design area, providing stability and support.

- Parallel Run: Multiple lines of stitches running parallel to each other, evenly distributed throughout the design area to ensure uniform coverage and stability.

- Zigzag or Back-and-Forth: Alternating zigzag stitches or back-and-forth stitches laid down in a grid pattern, creating a solid foundation for the embroidery design.

- Contour or Edge Run: Stitches laid down along the outer edges of the design area, defining the shape and providing stability to prevent distortion.

- Fill Stitch: A dense fill stitch pattern laid down in the background of the design area, providing additional support and coverage for the embroidery.

Techniques for Creating Underlay Stitch

- Digitizing Software: Use specialized embroidery digitizing software like Wilcom, Pulse, or Tajima DG/ML by Pulse to create and customize underlay stitch patterns.

- Manual Stitching: For more control and precision, digitize underlay stitch manually by selecting stitch types, lengths, and densities to suit the specific requirements of the design.

- Layering: Experiment with different types of underlay stitch and layering techniques to achieve the desired stability, density, and coverage for the embroidery design.

Best Practices for Underlay Stitch in Embroidery Digitizing

- Consider Fabric Type: Choose the appropriate type and density of underlay stitch based on the fabric type and characteristics to ensure optimal stability and coverage.

- Test and Adjust: Conduct test stitches on sample fabric to evaluate the effectiveness of the underlay stitch and make adjustments as needed to achieve the desired results.

- Balance with Top Stitches: Coordinate the density and stitch direction of underlay stitch with the top stitches to ensure balanced tension and proper coverage throughout the embroidery design.

- Minimize Density Buildup: Avoid excessive buildup of underlay stitch density, as it can cause stiffness or distortion in the fabric and affect the overall quality of the embroidery.

- Maintain Consistency: Maintain consistency in underlay stitch techniques and settings across different elements of the embroidery design to ensure uniformity and cohesion in the finished product.

Conclusion

Underlay stitch plays a critical role in embroidery digitizing, providing stability, density, and definition to embroidered designs. By understanding the importance of underlay stitch, exploring different types and techniques, and following best practices, embroiderers can achieve high-quality and precise embroidery results that enhance the overall appearance and durability of the finished product.

Embroidery digitizing involves intricate processes like underlay stitching to achieve high-quality results. If you’re looking for professional digitizing services to bring your embroidery designs to life, consider partnering with zdigitizing. With expertise in logo digitizing, 3D puff digitizing, cap digitizing, and applique digitizing, ZDigitizing ensures high-quality and precise embroidery designs that meet the needs of businesses and individuals alike. Let me know if you have any questions or need further assistance!