The world of manufacturing offers various methods to bring your product ideas to life. Two popular options are plastic molding and 3D printing. While both utilize plastic materials, they differ in process, capabilities, and suitability for specific projects. This comprehensive guide delves into the key distinctions between plastic molding and 3D printing, helping you make an informed decision for your next project.

If you’re looking for high-quality injection molding services in China, or need custom plastic molds manufactured, check out this reputable supplier.

Understanding Plastic Molding

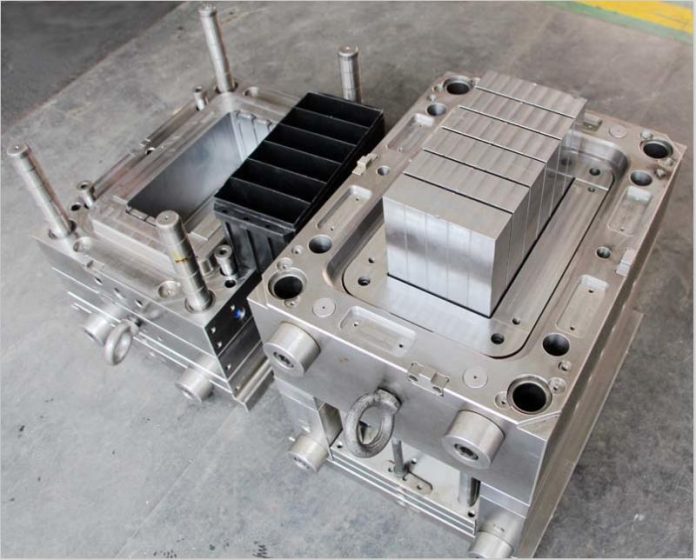

Plastic molding encompasses a range of techniques that involve creating a mold cavity resembling the desired final product. Molten plastic is injected into this cavity, fills it completely, and solidifies, taking the shape of the mold. Once cooled, the finished plastic part is ejected.

Here’s a table outlining the different types of plastic molding:

| Type of Plastic Molding | Description | Examples |

|---|---|---|

| Injection Molding | The most common method, involving injecting molten plastic under high pressure into a mold cavity. | Bottles, toys, automotive parts |

| Blow Molding | Creates hollow plastic parts by inflating a plastic tube inside a mold. | Bottles, containers, toys |

| Compression Molding | Presses heated plastic sheets into a mold cavity. | Electrical components, buttons, bottle caps |

| Rotational Molding | Fills a heated, rotating mold with powdered plastic, which melts and coats the mold’s inner surface. | Tanks, coolers, kayaks |

The Advantages of Plastic Molding

- High-volume production: Ideal for mass-producing identical plastic parts efficiently and cost-effectively.

- Superior surface finish: Produces parts with smooth, consistent finishes, crucial for aesthetic and functional applications.

- Dimensional accuracy: Ensures consistent and precise part dimensions throughout production runs.

- Wide material selection: Allows for utilizing various plastic types with diverse properties to meet specific project requirements.

- Strength and durability: Molded parts generally offer superior strength and durability compared to 3D-printed counterparts.

Exploring 3D Printing

3D printing, also known as additive manufacturing, builds three-dimensional objects layer by layer from a digital file. This technology uses various materials, including plastics, to create intricate and complex designs.

The Benefits of 3D Printing

- Rapid prototyping: Enables quick and cost-effective creation of prototypes for design verification and iteration.

- Design flexibility: Allows for intricate and complex geometries, often impossible with traditional manufacturing methods.

- Low-volume production: Ideal for small-batch production runs or customized items with minimal upfront costs.

- On-demand manufacturing: Enables decentralized and localized production, reducing lead times and transportation needs.

Choosing the Right Method: A Comparison

While both methods offer distinct advantages, the optimal choice hinges on your specific project requirements. Here’s a comparative breakdown to guide your decision:

| Factor | Plastic Molding | 3D Printing |

|---|---|---|

| Production volume | High | Low-to-medium |

| Cost per unit | Lower for high volumes | Higher for low volumes |

| Speed | Faster for high volumes | Faster for prototypes and low volumes |

| Design complexity | Moderate | High |

| Surface finish | Smooth and consistent | Layered and textured |

| Material selection | Wider range | Limited selection |

| Part strength | Generally stronger | Can vary depending on printing parameters |

When to Choose Plastic Molding

- Large-scale production runs: When you require a significant number of identical plastic parts.

- Cost-effectiveness for high volumes: As the cost per unit decreases with higher production quantities.

- Need for smooth surface finish: Particularly important for aesthetic or functional applications.

- Dimensional accuracy is critical: When precise part dimensions are essential for functionality.

- Wide range of material options required: To meet specific project needs regarding strength, flexibility, or other properties.

When to Choose 3D Printing

- Rapid prototyping: To quickly create and iterate on product designs before committing to full-scale production.

- Low-volume or customized production: For smaller batches or personalized items.

- Complex or intricate designs: When traditional manufacturing methods struggle to achieve the desired geometry.

- On-demand or localized manufacturing: To reduce lead times and transportation needs.