Key Takeaways:

- Shock-absorbing casters significantly reduce workplace noise and enhance safety.

- They protect sensitive equipment by minimizing vibrations during transport.

- Implementing these casters can lead to increased operational efficiency and reduced maintenance costs.

Table of Contents:

- Introduction

- Understanding Shock Absorbing Casters

- Benefits of Material Handling

- Real-World Applications

- Choosing the Right Casters

- Implementation Strategies

- Conclusion

Introduction

In today’s fast-paced material handling environments, businesses continually seek ways to boost efficiency, enhance safety, and protect valuable equipment. Surprisingly, one of the most impactful upgrades begins at ground level—with the wheels beneath your equipment. By integrating shock absorbing suspension casters, companies can revolutionize the way they move goods and machinery throughout their facilities.

These advanced casters are far from ordinary. They offer unique suspension systems designed to cushion impacts that would otherwise result in unnecessary wear, equipment damage, or workplace hazards. As logistical demands continue to rise, understanding the transformative effect of shock-absorbing casters is essential for any business seeking a competitive advantage.

Beyond simply rolling more quietly across the floor, these casters directly affect operational outcomes by creating a safer, quieter, and more productive work environment. When properly implemented, shock-absorbing technology not only extends the lifespan of your equipment but also reduces costly downtime caused by repairs or damaged goods.

As industries respond to increasing demands for efficiency and employee well-being, upgrading material handling systems with shock-absorbing casters is quickly becoming a best practice endorsed by facility managers and safety experts.

Understanding Shock Absorbing Casters

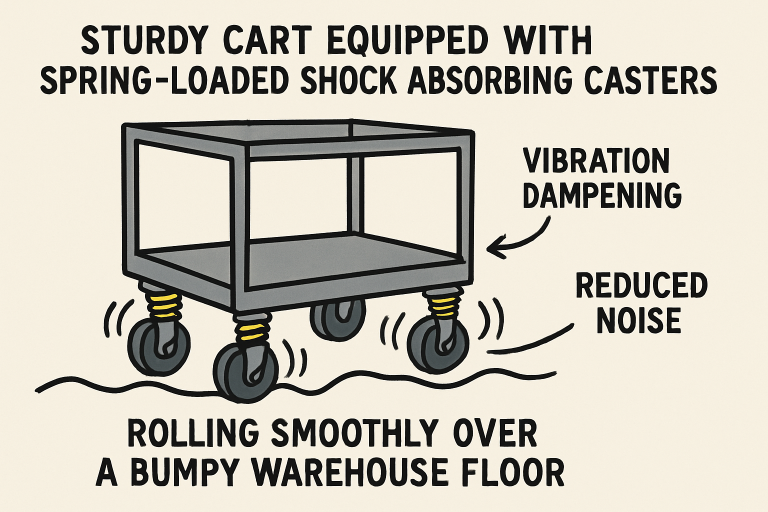

Shock absorbing casters are engineered with built-in suspension mechanisms—often using springs, elastomers, or pneumatic systems—to cushion the loads they support. As carts or machinery move across uneven surfaces or encounter bumps and debris, these casters compress, isolating vibrations and sudden jolts from the floor and cargo.

This technology has two benefits: it limits the transmission of force to sensitive materials during transport and protects flooring from undue stress, ultimately reducing maintenance needs throughout the facility. Shock absorbers within the caster assembly respond dynamically to varying weights and floor conditions, making them ideal for various manufacturing, warehousing, aviation, and healthcare applications.

Benefits of Material Handling

- Noise Reduction: Shock-absorbing casters can dramatically reduce the noise produced during material transport. Industrial workers routinely cite noise as a key source of both stress and distraction on the job. Studies have shown that certain caster designs can decrease noise levels by over 60%, supporting occupational health standards and encouraging focus.

- Protection of Sensitive Equipment: When material handling involves delicate instruments or products, such as laboratory devices or precision-machined parts, even mild shocks can cause costly damage or calibration errors. The vibration-dampening qualities of these casters help ensure product integrity throughout the supply chain.

- Increased Efficiency and Safety: The smoother transit offered by shock-absorbing casters reduces ergonomic risks and worker fatigue. Tasks are completed more quickly and with less exertion, minimizing the potential for workplace injuries and enhancing productivity overall. Additionally, this technology often extends the life of carts, trolleys, and floors, yielding savings on replacement and repairs.

Real-World Applications

The impact of shock-absorbing casters is evident across multiple sectors. In automotive manufacturing plants, for example, facility managers have reported fewer incidents of damaged vehicle parts during internal transport and improved morale from significant drops in noise pollution. After upgrading their caster systems, warehousing operations moving thousands of units daily have documented lower maintenance costs for carts and concrete floors.

One case study outlined how a major electronics manufacturer reduced equipment loss and downtime by nearly 30% after switching to shock-absorbing casters. This not only preserved product integrity but also streamlined logistics, paving the way for higher throughput and customer satisfaction.

Choosing the Right Casters

Selecting the ideal casters requires careful evaluation of your specific operational needs:

- Load Capacity: Assess the heaviest loads the casters will bear and ensure each caster is rated to safely support this weight, distributed evenly across all wheels on a cart or piece of equipment.

- Wheel Material: Depending on your needs for durability, chemical resistance, and floor protection, choose from polyurethane, rubber, pneumatic, or thermoplastic wheels.

- Environmental Conditions: Consider factors such as room temperature, humidity, and potential exposure to oils or solvents that might affect the casters’ lifespan or functionality.

- Mobility Needs: Determine whether your operations require fixed or swivel casters for maximum maneuverability in tight spaces.

Implementation Strategies

- Assess Current Equipment: Review all carts, dollies, and transport mechanisms for compatibility with new caster models. Note that modifications or retrofits will be required to accommodate the upgraded wheels.

- Consult with Experts: Collaborate with manufacturers or material handling consultants to identify the best shock-absorbing caster models for your industry, facility conditions, and workloads.

- Train Staff: Ensure employees understand the correct installation and use of new casters. Training should cover load limits, mobility considerations, and routine inspection practices to maximize the performance and lifespan of the investment.

For further insights on optimizing your material handling practices, see IndustryWeek’s guide to material handling.

Conclusion

Shock-absorbing casters are a simple yet powerful upgrade for any material handling operation. Their ability to dampen noise, protect valuable assets, and accelerate workflow can yield dividends in safety, productivity, and cost-efficiency. By carefully choosing and implementing these casters, businesses can ensure a smoother journey for their goods and a safer, quieter workplace for their people.