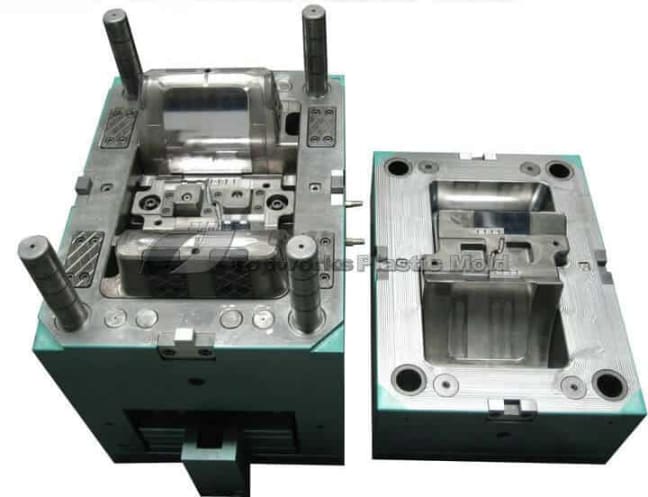

China remains a global leader in injection mold manufacturing, offering high-quality molds at competitive prices. However, navigating the process of buying PET preform molds or bumper molds from Chinese suppliers can be daunting, especially for first-time buyers. This guide aims to demystify the process by providing a step-by-step approach to ensure a smooth and successful experience.

For high-quality preform molding equipment and bumper mold manufacturing capabilities, these links may prove valuable.

Step 1: Define Your Needs

Before embarking on your sourcing journey, clearly define your requirements. Consider the following:

- Mold type: Do you need a PET preform mold for creating plastic bottles or a bumper mold for automotive parts?

- Cavity number: This determines how many parts are produced per molding cycle. Higher cavities translate to faster production but at a higher upfront cost.

- Material compatibility: Ensure the mold material is compatible with the plastic type you intend to use.

- Design specifications: Provide detailed drawings and specifications for the desired mold, including dimensions, tolerances, and surface finishes.

Tip: Consulting with an experienced injection molding professional can help you define your needs accurately and avoid costly mistakes.

Step 2: Find the Right Supplier

Finding the right PET preform mold or bumper mold supplier is crucial. Here are some strategies:

- Online marketplaces: Utilize established B2B platforms like Alibaba or Global Sources to connect with a wide range of Chinese mold manufacturers.

- Industry directories: Trade associations and industry publications often maintain directories of reputable mold makers.

- Recommendations: Seek recommendations from colleagues, industry professionals, or existing manufacturers you trust.

When evaluating potential suppliers, consider factors like:

- Experience: Prioritize manufacturers with a proven track record in producing PET preform molds or bumper molds to your specifications.

- Capabilities: Ensure the supplier has the necessary equipment and expertise to fulfill your mold requirements.

- Quality control: Look for suppliers with robust quality control processes to guarantee mold quality and consistency.

- Communication: Choose a supplier with excellent communication skills to ensure clear and effective collaboration throughout the project.

Pro Tip: Don’t limit yourself to the first supplier you find. Compare quotes and capabilities from several vendors before making a decision.

Step 3: Negotiate and Finalize the Contract

Once you’ve chosen a supplier, negotiate the price, payment terms, and delivery schedule.

- Price: While cost is important, focus on the overall value proposition, considering factors like quality, lead time, and after-sales support.

- Payment terms: Establish clear payment terms, including deposit amount, milestones for progress payments, and final payment upon delivery and inspection.

- Delivery schedule: Negotiate a realistic delivery schedule that aligns with your production needs.

- Warranty: Ensure the contract outlines the warranty terms covering defects in materials or workmanship.

Remember: Carefully review the contract and address any concerns before signing.

Step 4: Monitor Production and Quality Control

Maintaining open communication with your supplier during production is essential.

- Regular updates: Request regular progress updates from the supplier, including photos and/or videos of the mold under development.

- Quality control: If possible, arrange for a third-party inspection of the mold before shipment to verify its compliance with your specifications.

Early intervention: Addressing any potential issues promptly can help avoid delays and ensure the final product meets your expectations.

Step 5: Delivery and Inspection

Upon receiving the PET preform mold or bumper mold, thoroughly inspect it for any damage or discrepancies.

- Visual inspection: Check for any visible defects on the mold surface, such as cracks, scratches, or uneven finishes.

- Dimensional inspection: Verify that the mold dimensions and tolerances align with your specifications.

- Performance testing: Conduct trial runs with the mold to ensure it produces parts consistently and with the desired quality.

Prompt communication: If you encounter any issues during inspection, immediately notify your supplier and work collaboratively to find a resolution.

Conclusion

Buying PET preform molds or bumper molds from China can be a cost-effective solution for many businesses. By following these steps, you can navigate the process efficiently, minimize risks, and ensure you receive high-quality molds that meet your specific needs.

Additional Considerations:

- Cultural differences: Be mindful of cultural differences when communicating with Chinese suppliers.

- Intellectual property: Protect your intellectual property rights by securing appropriate agreements with your chosen manufacturer.

- Import regulations: Familiarize yourself with import regulations and customs clearance