Butterfly valves are widely used in various industries due to their compact design, efficient operation, and cost-effectiveness. These quarter-turn valves regulate fluid flow using a rotating disc, making them ideal for applications requiring quick shutoff and precise throttling. Their lightweight construction and ease of installation make them a preferred choice for both small and large-scale fluid systems.

This article explores the working principle, types, advantages, and common uses of butterfly valves.

How Do Butterfly Valves Work?

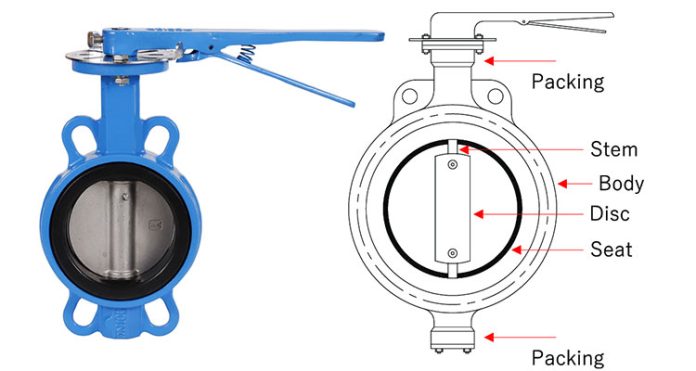

Butterfly valves function by using a rotating disc positioned in the center of the pipeline. The disc is connected to a stem, which is turned by a handle, gearbox, or actuator. When the valve is fully open, the disc aligns with the flow, allowing minimal resistance. When closed, the disc rotates perpendicular to the flow, blocking passage and stopping fluid movement.

A highly efficient choice for industrial flow control is butterfly valves, offering reliable performance in various applications.

Types of Butterfly Valves

There are several types of butterfly valves, each designed for specific applications:

- Concentric (Rubber-Lined) Butterfly Valves

- The most common type, featuring a central stem and a rubber-seated disc.

- Suitable for low to medium-pressure applications.

- Double-Offset (High-Performance) Butterfly Valves

- The stem is slightly offset, reducing wear and improving sealing performance.

- Ideal for high-pressure and high-temperature conditions.

- Triple-Offset Butterfly Valves

- Features three offsets to eliminate friction and ensure a bubble-tight seal.

- Used in critical applications such as oil, gas, and chemical industries.

- Lug and Wafer Butterfly Valves

- Wafer valves fit between flanges with minimal space requirements.

- Lug valves have threaded inserts, allowing easy installation and removal.

Benefits of Butterfly Valves

- Compact and Lightweight – Requires less space compared to other valve types, reducing installation costs.

- Quick Operation – Quarter-turn movement enables fast opening and closing.

- Energy Efficient – Minimal pressure drop ensures smooth fluid flow.

- Durable and Low Maintenance – Fewer moving parts result in longer service life and reduced maintenance.

- Cost-Effective – More affordable than gate or ball valves, making them ideal for large-scale applications.

Common Applications of Butterfly Valves

Butterfly valves are used in a wide range of industries, including:

- Water Treatment – Regulating water flow in distribution and sewage systems.

- HVAC Systems – Controlling air and water flow in heating and cooling applications.

- Oil and Gas Industry – Managing fuel and gas flow in pipelines and processing plants.

- Chemical Processing – Handling corrosive and high-temperature fluids.

- Power Generation – Used in steam and cooling water systems.

Conclusion

Butterfly valves provide an efficient and cost-effective solution for flow control in various industries. Their versatility, durability, and ease of operation make them a popular choice for applications requiring quick shutoff and precise regulation. Whether in water treatment, oil and gas, or chemical processing, these valves enhance system performance while minimizing operational costs.