A filling machine is a significant investment. A reputable filling machine supplier will help you choose a model that fits your production needs and can grow with your business.

Different machines are designed to work with different kinds of containers and materials. Liquids have different viscosities, and these characteristics dictate the best type of machine to use.

Choose a Manufacturer

When you purchase a powder-filling machine, it is important to choose a manufacturer who understands your product. Different types of products require different kinds of machines, and the right equipment will allow you to reach your production goals. This includes factors like product density and the way that your product will be packaged. For instance, if your product is going to be shipped in a box, you will need to select a machine that can adjust to changing environmental conditions.

One company that understands your needs is Spee-Dee Packaging Machinery, which offers a wide variety of powder-filling machines to fit your specific application. These machines are designed with each client’s formulation in mind and can accommodate a variety of free-flowing and non-free-flowing products. The company also provides comprehensive customer service, including startup assistance, phone support, and field service. In addition, the company has a test lab that can help you determine which machine is the best for your product.

Consider Your Needs

The type of product and material you produce determines what kind of filling machine you will need. Bottles, jars, vials, and ampoules all have different sizes and shapes that require the right equipment to fit them. Also, some products are prone to shearing during production which can change the viscosity of the liquid. These are considerations you will need to discuss with your supplier to ensure they understand your product and what you will need from the machine.

You will want to think about how much output you will need based on consumer demand. This will help you figure out how many machines you will need to meet your daily production goals. It is also a good idea to look into the future and consider how you might need to grow your business in the future.

Finally, you will want to think about the cleaning and maintenance needs for your machinery. You will need to find a machine that is easy to clean and hygienic to prevent the growth of bacteria and other contaminants. This can be achieved by looking for a machine that has no dead legs, uses wash-down electrical components in the product area, and has a simplified design to eliminate nooks and crannies where microorganisms can hide.

Do Your Research

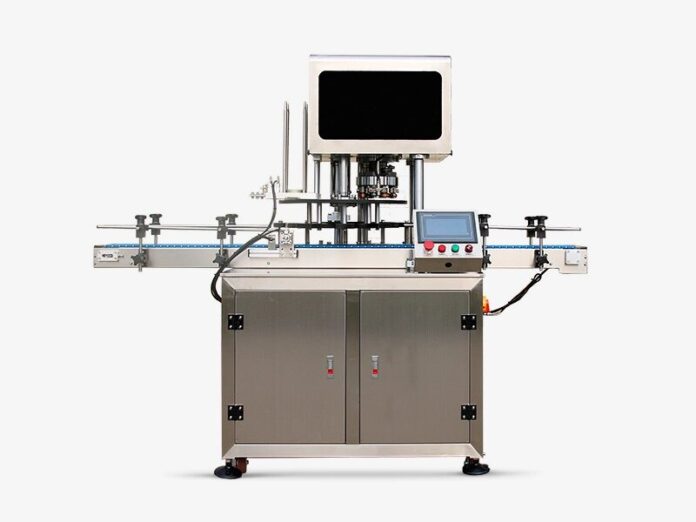

Filling machines are a critical piece of manufacturing equipment that help businesses package their products for shipment. They are typically located at the end of production lines and can be used to pack industrial ingredients as well as commercial and consumer goods.

Choosing the right machine for your needs requires research and careful consideration. The type of product you’re packaging will dictate the type of machine that’s needed, as different machines are designed for different materials and containers. For example, liquids of varying viscosities require different designs. A sticky liquid can clog machinery and cause unwanted changes in the liquid’s state, whereas a suspension or liquid containing pulp needs a machine that’s designed to prevent clogging.

Other factors to consider include changeover times. You want to find a manufacturer that can reduce changeover times and make the process as seamless as possible. You also want to ensure that the machine you choose is compatible with other machines in your line, such as capping machines.

Ask Questions

When choosing a liquid filling machine, it is important to ask the right questions. These questions will help ensure that the machine you purchase is a good fit for your company’s needs and will allow you to maximise your return on investment.

First, it’s essential to understand your business and your future production plans. Knowing how much you want to produce now and in the future will help the supplier recommend the best machine to meet your needs.

It’s also important to consider the type of product you will be packaging. For example, foaming products require a different technology than water bottles. Similarly, carbonated liquids require a special machine that can handle high pressure. Finally, it’s critical to ask about the machine’s accuracy and if it can work with a variety of bottle sizes. This will save you from spending money on a machine that cannot meet your needs.