In the fast-evolving world of manufacturing, the synergy between technology and material science plays a pivotal role in defining the efficiency and quality of the end products. Two of the most transformative technologies reshaping the manufacturing landscape are 3D printing and CNC machining. While 3D printing offers unparallelled flexibility in layer-by-layer construction, CNC machining brings precision and strength through its subtractive methodologies. However, the full potential of these technologies can only be realised through a thorough understanding and application of compatible materials.

Choosing the right material is not just about leveraging the strengths of a technology but also about enhancing functionality, durability, and cost-effectiveness of the manufactured parts. This article delves deep into the materials that sit at the crossroads of 3D printing and CNC machining. It explores how material compatibility influences design decisions, impacts product performance, and drives innovation across industries. By comparing the materials commonly used in both technologies, we aim to provide insights that help manufacturers make informed decisions, pushing the boundaries of what’s possible in modern manufacturing.

Importance of Material Selection in Achieving Optimal Results for Both 3D Printing and CNC Machining

Material selection stands as a critical pillar in the realm of manufacturing, especially when employing cutting-edge technologies like 3D printing and CNC machining. The choice of material not only influences the manufacturing process itself but also significantly impacts the performance, durability, and application of the final product. Understanding the interplay between materials and these technologies is essential for optimising both the production process and the functionality of manufactured parts.

1. Achieving Desired Mechanical Properties

For both 3D printing and CNC machining, the mechanical properties of the selected materials, such as strength, flexibility, and durability, dictate the practical applications of the final product. In aerospace and automotive industries, where safety and reliability are paramount, materials must withstand extreme conditions without failure. For instance, titanium and reinforced composites are favoured in 3D printing for critical aerospace components due to their high strength-to-weight ratios, while aluminium and steel are preferred in CNC machining for their durability and machinability.

2. Ensuring Process Compatibility

Each manufacturing technology has specific requirements that make certain materials more suitable than others. In 3D printing, materials must be capable of being deposited layer by layer, which necessitates a particular flow and solidification characteristic. Plastics like PLA and ABS are popular in 3D printing for their ease of melting and shaping. Conversely, CNC machining demands materials that can withstand the physical stress of being cut, drilled, or milled. Hard metals like steel and brass are commonly used in CNC processes due to their ability to maintain integrity under high-stress operations.

3. Enhancing Product Aesthetics and Functionality

The aesthetic qualities of a material, such as colour, finish, and texture, are crucial for consumer products and are heavily influenced by the chosen manufacturing method. 3D printing allows for intricate designs and customisation that are not possible with traditional manufacturing methods, utilising materials that can achieve a high-quality finish directly out of the printer. In contrast, materials used in CNC machining must be suitable for achieving a smooth, polished surface through subtractive processes.

4. Cost-Effectiveness and Sustainability

Material costs can significantly affect the overall economics of a manufacturing project. Materials that are readily available and easy to process can reduce costs for both 3D printing and CNC machining. Furthermore, sustainability concerns are pushing manufacturers to consider the environmental impact of their material choices. Biodegradable plastics for 3D printing and recyclable metals for CNC machining are becoming increasingly popular as industries move towards greener manufacturing practises.

5. Facilitating Innovation

The exploration of new materials and combinations thereof can lead to groundbreaking applications and new markets. For example, the use of conductive materials in 3D printing is opening up possibilities in electronics, such as 3D-printed sensors and circuits. Similarly, the use of compositae materials in CNC machining is expanding the capabilities of products in terms of weight reduction and improved thermal properties.

The strategic selection of materials is therefore not just a matter of matching a material to a manufacturing process; it is about unlocking the potential of 3D printing and CNC machining to innovate, improve, and inspire. By carefully considering the properties required of the final product, manufacturers can select materials that enhance both the process and the product, leading to superior outcomes and pushing the boundaries of what is possible in modern manufacturing.

Understanding the Basics

The advent of 3D printing and CNC machining has profoundly reshaped the manufacturing landscape. These technologies not only offer distinct advantages and challenges but also cater to diverse material needs and production methodologies. Understanding the basic principles and capabilities of each technology is crucial for leveraging their potential in various industrial applications.

Definition and Core Principles of 3D Printing

3D Printing, or additive manufacturing, entails the creation of three-dimensional objects through the layering of materials guided by digital models. This process starts with a digital design, usually crafted in a CAD (Computer-Aided Design) software, which is then divided into thin horizontal layers by specialised software. The printer constructs the object from the bottom up, layer by layer, by extruding or curing material in precise patterns.

Core Principles:

- Layer-by-Layer Fabrication: This allows for the creation of complex geometries, allowing for hollow parts and intricate internal features that are challenging or unachievable with conventional manufacturing methods.

- Material Efficiency: Minimal waste production as material is added rather than removed.

- Customisation: Facilitates the production of customised items without the need for new tools or moulds for each new design.

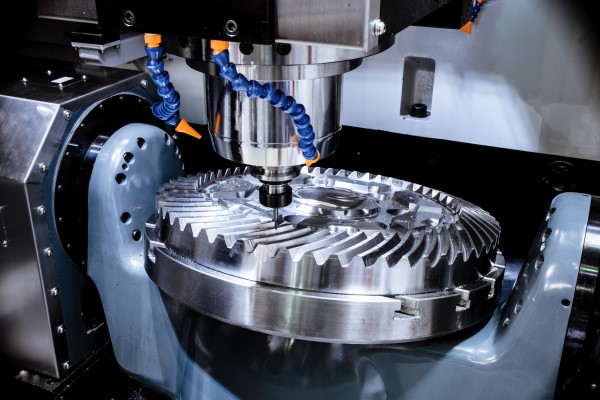

Definition and Core Principles of CNC Machining

CNC Machining refers to the subtractive manufacturing process where material is removed from a solid block using various controlled cutting tools like drills, lathes, or mills. This technology uses pre-programmed computer software to control the movement of factory tools and machinery. The process begins with a solid block of material, which is precisely cut into the desired shape and dimensions.

Core Principles:

- Subtractive Process: Material is cut away to form the shape of the part, contrasting with additive processes like 3D printing.

- Precision and Repeatability: High accuracy and consistency are achievable, making it ideal for production runs that require exact replicates.

- Material Versatility: Although it can work with a wide range of materials, the physical characteristics of the material (such as hardness and brittleness) can limit the complexity of the design.

Comparison of Material Constraints and Capabilities

When comparing 3D printing and CNC machining, it’s essential to consider how each technology deals with material constraints and their capabilities:

- Material Form: 3D printing typically uses powders, filaments, or resins, which may limit the types of materials that can be used but also allows for the creation of compositae materials and graded structures. CNC machining starts with solid blocks, bars, or sheets, thus requiring materials that can withstand significant mechanical stress during the cutting process.

- Complexity and Design Freedom: 3D printing excels at creating complex and intricate designs that would be challenging or unachievable with CNC machining. On the other hand, CNC machining is superior for creating parts that require extremely tight tolerances and smooth finishes.

- Production Speed and Scalability: 3D printing can be slower, particularly for high-volume production, but it offers faster setup times for small production runs or custom items. CNC machining is more time-consuming in setup for each new part but may be more efficient for large-scale production of simpler designs.

- Cost Implications: The cost-effectiveness of each technology varies depending on the production volume, material cost, and the labour involved. 3D printing can reduce the cost of entry for small, customised batches, whereas CNC machining might be more cost-effective at scale despite higher initial setup costs.

Both 3D printing and CNC machining have transformed manufacturing, each bringing distinct advantages to the table. By understanding their foundational principles and how they interact with different materials, manufacturers can more effectively determine which method is best suited for their specific needs and applications.

Common Materials Used in 3D Printing

3D printing has revolutionised manufacturing, enabling the creation of complex and customised products with unmatched ease. The variety of 3D printing materials that can be used continues to expand, each offering unique properties and making the technology suitable for a wide range of applications across different industries. These materials not only enhance the versatility of 3D printing but also cater to specific requirements, broadening the scope of innovation and customisation in modern manufacturing.

Plastics

- PLA (Polylactic Acid): PLA is a biodegradable thermoplastic made from renewable resources like corn starch or sugarcane. It is one of the most popular materials in 3D printing because of its ease of use, low cost, and eco-friendly properties. PLA prints at a lower temperature than most thermoplastics, which makes it less prone to warping, and is ideal for producing items like household goods, prototypes, and educational models.

- ABS (Acrylonitrile Butadiene Styrene): Renowned for its strength and durability, ABS is a petroleum-based plastic commonly used in professional and industrial applications. It requires a higher printing temperature than PLA, making it more prone to warping and emitting fumes during printing. Its superior toughness and ability to withstand higher temperatures make it ideal for creating functional parts such as automotive components, electronic housings, and toys.

- PETG (Polyethylene Terephthalate Glycol): PETG is a variant of polyester that is modified with glycol to reduce brittleness. This material combines the ease of printing seen in PLA with the strength and durability similar to ABS. It is also highly resistant to moisture and many chemicals, making it ideal for products that require a sterile environment, such as medical braces and food containers.

Metals

- Titanium: Renowned for its high strength, low weight, and outstanding corrosion resistance, titanium is frequently used in aerospace, automotive, and medical applications. It is particularly valued in the aerospace industry for manufacturing complex components that benefit from weight reduction without sacrificing strength.

- Stainless Steel: Stainless steel in 3D printing is often used to produce industrial parts, tools, and prototypes that benefit from its robustness, resistance to corrosion, and aesthetic appeal. It is also used for culinary tools, jewelry, and surgical implements, where corrosion resistance is crucial.

- Aluminium: Known for its light weight and strength, aluminium is used in 3D printing primarily for applications where reducing weight is essential, such as parts for drones and bicycles. It also features good thermal and electrical conductivity, making it suitable for a variety of functional applications.

Composites and Other Emerging Materials

- Carbon Fibre Reinforced Polymers: These materials are plastics (often nylon) infused with carbon fibre, offering increased stiffness, strength, and temperature resistance. They are used in applications that require the lightweight properties of carbon fibre combined with the versatility of 3D printing.

- Graphene-Infused Filaments: Graphene is used to enhance the properties of standard 3D printing materials, adding improved thermal and electrical conductivity. This makes it ideal for wearable electronics and high-performance aerospace components.

- Conductive Filaments: These are designed to carry an electrical charge, enabling the production of custom electronic components and touch sensors directly from the printer.

Each material brings distinct properties to the table, making the choice of material as important as the design of the item itself. Understanding these materials helps innovators and manufacturers select the right material for their specific needs, whether they’re creating single prototypes or large-scale production runs, thereby fully leveraging the capabilities of 3D printing technology.

Common Materials Used in CNC Machining

CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, known for its precision and versatility in producing parts across diverse industries. The choice of material in CNC machining significantly influences both the process and the quality of the final product. Here’s an overview of the most commonly used materials in CNC machining and their intrinsic properties that make them suitable for various applications.

Metals

- Aluminium: Lightweight yet strong, aluminium is one of the most popular metals used in CNC machining. It is relatively easy to machine, has excellent thermal and electrical conductivity, and offers good strength-to-weight ratios. Aluminium is widely used in the aerospace, automotive, and consumer electronics sectors for parts like engine components, enclosures, and chassis.

- Steel: Known for its robustness and durability, steel is another commonly machined metal. It comes in various alloys, with stainless steel being particularly valued for its corrosion resistance. CNC machined steel parts are prevalent in the construction, automotive, and manufacturing industries, ideal for producing structural components, tools, and high-strength fittings.

- Brass: Brass is a copper and zinc alloy, known for its machinability and aesthetic qualities, making it a preferred choice for decorative items. It also has excellent acoustic properties and is non-sparking, making it suitable for musical instruments, fixtures, and applications in explosive environments.

Plastics and Polymers

- Nylon: Nylon is a synthetic polymer known for its strength, wear resistance, and flexibility. It’s often used in CNC machining for producing functional prototypes and end-use parts that require durability and resistance to abrasion. Typical applications include gears, bearings, and other components where toughness is required.

- Acrylic: Also known as polymethyl methacrylate (PMMA), acrylic is valued for its clarity and resistance to weathering, making it an excellent choice for optical applications and consumer products. It is commonly used in the manufacturing of windows, lenses, and signs where a clear, glass-like appearance is desirable.

Wood and Other Soft Materials

- Wood: Wood’s natural beauty and workability make it a popular choice for CNC machining, especially for furniture, decor, and architectural applications. Various types of wood, including hardwoods such as oak and softwoods like pine, offer a range of properties in terms of strength, grain patterns, and finishing capabilities.

- Foam: Foam is another material frequently used in CNC machining, especially for prototyping and modelling. Its ease of cutting and ability to form complex shapes quickly makes it ideal for mock-ups and architectural models.

Analysis of Material Characteristics Important for CNC Machining

- Machinability: The ease with which a material can be cut is a critical consideration. Materials like aluminium and brass are known for their excellent machinability, allowing for higher cutting speeds and less wear on tools.

- Strength and Hardness: The strength of a material often dictates its use in load-bearing applications, while hardness can affect the wear resistance of the final product. Steel is particularly valued for its high strength and hardness, which are crucial in many engineering applications.

- Thermal and Electrical Conductivity: Certain applications require materials with specific conductivity properties. For instance, aluminium is often used in heat sinks and other applications requiring good thermal conductivity.

- Aesthetic Qualities: For applications where the visual appearance of the part is important, materials like acrylic and brass are chosen for their finish and decorative appeal.

- Cost and Availability: The cost of raw materials and their availability can significantly affect the choice of material for a project. Factors such as supply chain reliability and material costs must be considered to ensure project viability.

Understanding these material characteristics helps manufacturers select the best material for their specific CNC machining projects, balancing between performance requirements and cost-efficiency to produce high-quality parts.

Comparative Analysis of Material Compatibility

In the manufacturing industry, the compatibility of materials with various technologies is a crucial consideration. Both 3D printing and CNC machining offer distinct advantages, but only a subset of materials can be effectively used with both methods. Understanding which materials are compatible with both technologies, as well as their advantages and limitations, is essential for optimising manufacturing processes and product performance.

Materials Compatible with Both 3D Printing and CNC Machining

Several materials demonstrate good compatibility with both 3D printing and CNC machining, making them versatile options for diverse manufacturing needs:

- Metals like Aluminium and Stainless Steel: These metals are popular in both 3D printing and CNC machining. Aluminium is favoured for its lightweight and excellent machinability, making it ideal for aerospace and automotive parts. Stainless steel is prised for its strength and corrosion resistance, making it ideal for medical devices and kitchenware.

- Plastics such as ABS and Nylon: ABS is widely used in both 3D printing and CNC machining for its strength and heat resistance, making it suitable for functional prototypes and consumer goods. Nylon, known for its durability and flexibility, is used in both methods for producing gears and functional components.

Advantages of Using Certain Materials in Both Technologies

Using materials that are compatible with both 3D printing and CNC machining offers several advantages:

- Flexibility in Manufacturing Process: Manufacturers can choose the most suitable method based on other factors like production volume or complexity without being limited by material choice.

- Consistency in Material Properties: Using the same material across different manufacturing methods can ensure that the physical properties of the parts remain consistent, which is essential for applications demanding high reliability and precision.

- Cost Efficiency: Stocking a single type of material for different production methods can reduce costs and simplify the supply chain.

- Hybrid Manufacturing Approaches: Some parts may benefit from being initially 3D printed to achieve complex geometries and then finished with CNC machining to obtain high precision and smooth surfaces.

In conclusion, the thoughtful integration of compatible materials in both 3D printing and CNC machining is key to unlocking the full potential of these technologies. This integration not only enriches the manufacturing process but also propels the industry toward more innovative, efficient, and sustainable production practises. The continued exploration and understanding of material properties will remain central to the evolution of manufacturing technologies. As CNC machining and 3D printing services continue to evolve, they offer unparallelled opportunities for experimenting with a wide range of materials, improving the capacity to customise products for specific needs and applications. This compatibility not only optimises manufacturing processes but also significantly influences the innovation and efficiency achievable in modern production environments. The ongoing exploration and application of these materials will undoubtedly shape the future of manufacturing, pushing the boundaries of what can be created and accomplished.