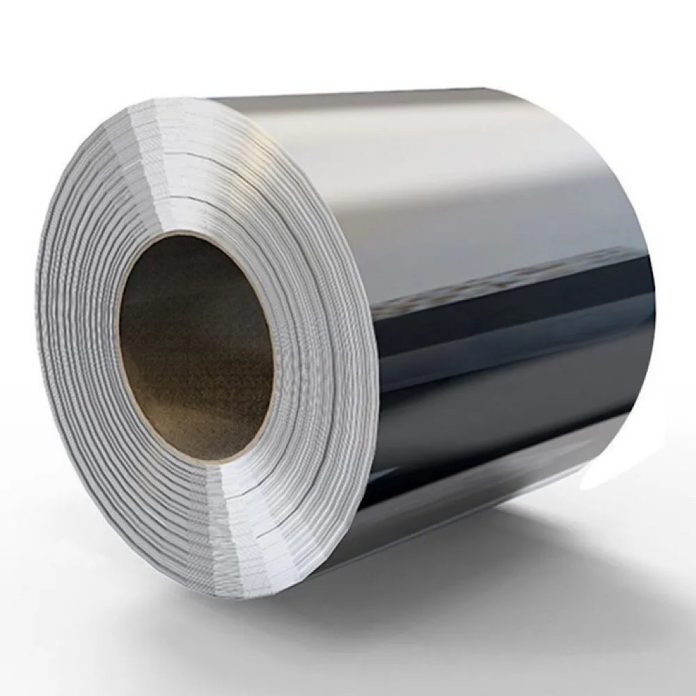

Hastelloy C276, a nickel-molybdenum-chromium alloy, is renowned for its exceptional resistance to a wide range of corrosive environments. One of the many forms in which this remarkable material is available is Hastelloy C276 foil. In this article, we will delve into the world of Hastelloy C276 foil, exploring its composition, properties, and the diverse applications that make it a vital material in industries where corrosion resistance is of utmost importance.

Composition of Hastelloy C276

Hastelloy C276 is a member of the Hastelloy family, which is known for its exceptional resistance to corrosion, particularly in harsh and aggressive environments. The composition of Hastelloy C276 consists of the following key elements:

- Nickel (Ni): Nickel is the primary component of Hastelloy C276, accounting for approximately 57% of its composition. Nickel is essential for enhancing the material’s corrosion resistance, ductility, and strength.

- Molybdenum (Mo): Molybdenum, constituting about 16-17% of Hastelloy C276, plays a critical role in providing resistance to localized corrosion, such as pitting and crevice corrosion. It also contributes to the alloy’s overall strength.

- Chromium (Cr): Chromium, at around 15-16%, adds to the alloy’s resistance to a wide range of corrosive substances. It helps in the formation of a passive oxide layer on the surface, preventing further corrosion.

- Tungsten (W): In small quantities, tungsten enhances the material’s resistance to high-temperature and high-velocity corrosive environments.

- Iron (Fe): Iron, though present in Hastelloy C276, is intentionally kept at low levels (less than 5%) to minimize the risk of sensitization, which can lead to intergranular corrosion.

- Other Elements: Hastelloy C276 may also contain trace amounts of different elements, such as carbon, sulfur, cobalt, and silicon, depending on the specific manufacturing process and requirements.

Properties of Hastelloy C276 Foil

Hastelloy C276 foil inherits the remarkable properties of the alloy it is derived from, making it an excellent choice for applications where corrosion resistance is a paramount concern. Here are some of the fundamental properties that make Hastelloy C276 foil stand out:

- Outstanding Corrosion Resistance: Hastelloy C276 foil is highly resistant to a wide range of corrosive substances, including acids, salts, and chemicals. It can withstand environments where other materials would quickly deteriorate, making it ideal for applications in the chemical processing, petrochemical, and pharmaceutical industries.

- High-Temperature Resistance: Hastelloy C276 foil retains its exceptional corrosion resistance even at elevated temperatures. It can perform well in applications where both high temperatures and aggressive chemicals are present.

- Versatility: The foil form of Hastelloy C276 is incredibly versatile, as it can be easily formed, cut, or shaped to meet specific design requirements. This adaptability is particularly advantageous for complex components in various industries.

- Mechanical Strength: Hastelloy C276 foil offers good mechanical strength, making it suitable for structural components, fasteners, and equipment subject to mechanical stress.

- Weldability: Hastelloy C276 foil can be welded using various methods, allowing for the fabrication of complex structures and equipment.

Applications of Hastelloy C276 Foil

This foil plays a pivotal role in various industries where corrosion resistance is a critical requirement. Its unique combination of properties makes it the material of choice for a wide range of applications, including but not limited to:

- Chemical Processing: The chemical processing industry relies on this foil for the construction of reaction vessels, pipes, and pumps. Its resistance to corrosive chemicals and high temperatures ensures the safe and efficient operation of chemical facilities.

- Petrochemical Industry: In the petrochemical sector, this foil is used for components in oil refining and gas processing plants, where exposure to aggressive chemicals and high temperatures is expected.

- Pharmaceutical Manufacturing: Pharmaceutical companies employ this foil for equipment used in drug manufacturing processes. Its corrosion resistance and biocompatibility make it a reliable choice for pharmaceutical applications.

- Desalination Plants: This foil is used in desalination plants, which convert seawater into freshwater. The foil’s resistance to saltwater corrosion is essential for the longevity of equipment in these facilities.

- Pollution Control Equipment: In the field of pollution control, this foil is utilized for flue gas desulfurization systems and industrial scrubbers, where it helps mitigate the harmful effects of pollutants on equipment.

- Oil and Gas Exploration: The oil and gas industry employs this foil for various components, such as downhole tubing and casings, where resistance to sour gas, high pressures, and high temperatures is crucial.

- Aerospace and Defense: Hastelloy C276 is also used in aerospace and defense applications, where its resistance to aggressive chemicals and extreme environmental conditions makes it a valuable material for critical components.

- Power Generation: Power plants, both nuclear and conventional, use this foil for steam generator tubes, heat exchangers, and other components exposed to high temperatures and corrosive environments.

- Pulp and Paper Industry: In the pulp and paper industry, this foil is employed for chemical processing equipment, as it can withstand the corrosive chemicals used in the papermaking process.

- Water Treatment: The foil form of Hastelloy C276 is utilized in water treatment facilities, where it is exposed to aggressive chemicals used to purify water. Its corrosion resistance ensures the durability and reliability of equipment in this field.

Conclusion

Hastelloy C276 foil is a remarkable material with a unique combination of properties that make it an essential choice for applications in industries where corrosion resistance is paramount. Its versatility, outstanding corrosion resistance, and high-temperature performance have solidified its reputation as a key player in chemical processing, petrochemical, pharmaceutical, and various other sectors. As industries continue to evolve, Hastelloy C276 foil will remain a reliable and indispensable material, ensuring the longevity and integrity of critical equipment in the face of harsh and corrosive environments. Its adaptability and extraordinary properties make it a material that continually shapes the future of industrial applications across the globe.